Dongguan Qiren Electronics specializes in manufacturing high-quality, durable Stamping Terminals with precision EDM stamping technology. Leveraging 20+ years of expertise, Qiren optimizes production to deliver low-cost solutions while ensuring ±0.0015mm accuracy and Ra0.

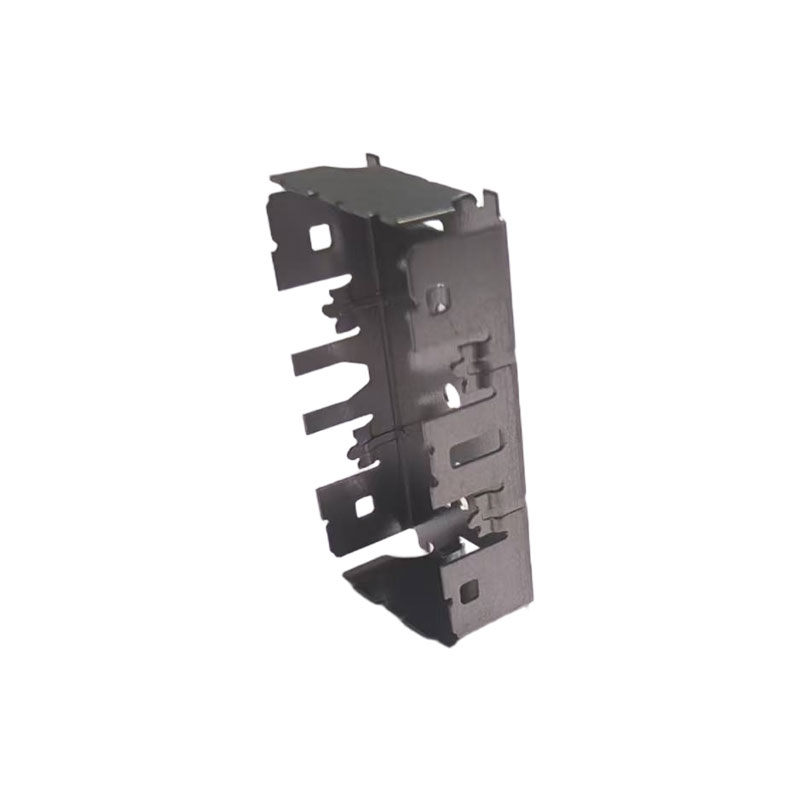

The hardware stamping department of Dongguan Qiren Electronics Co., Ltd. is committed to providing customers with cost-effective precision hardware mold stamping terminal manufacturing services. We effectively reduce customers' mold costs by optimizing production processes, strictly controlling supply chains and large-scale production. Our stamping processing has more than 20 years of industry experience, and precision stamping technology ensures high precision and stability of molds while shortening delivery cycles. Whether it is a small or medium-sized enterprise or a multinational manufacturer, we can provide cost-effective mold solutions. Choose Qiren Electronics to get higher quality molds at a lower cost

When 0.08mm terminal spacing becomes the life and death line of the 5G era, who is using "atomic engraving" to reshape the connector rules?

In the battlefield where the Type-C interface plating deviation of 0.003mm means signal loss, and in the extreme track where the high-voltage terminals of new energy vehicles require 1 million plug-in and unplugging with zero wear, the EDM stamping mold process is using a contact accuracy of ±0.0015mm to allow copper alloys to be reborn as superconductors in the conductive world in 800℃ discharge pulses!

When mechanical stamping leaves fatal burrs on 0.15mm thick phosphor copper sheets, and when laser cutting causes arc risks on 24-pin Micro USB interfaces, our 6-axis intelligent EDM system is using 0.02mm tungsten wire to carve 128 array contacts on 62HRC carbide that are more accurate than chip pins! 5G base station shrapnel, smart wearable FPC connector, 800V fast charging mother socket... These "ghost orders" that caused Japanese companies' quotations to soar by 300% were delivered in 12 hours!

● Nano-pulse annihilation: 0.00005-second discharge control, contact surface roughness reaches Ra0.08μm

● Intelligent stress reorganization system: dynamic compensation for material rebound, 0.1mm ultra-thin terminal flatness error <0.002mm

● Ultra-dense matrix annihilator: 128-pin 0.2mm pitch terminal mold processing one-time molding, precision CPK≥2.33

● Trillion-time life black technology: multi-layer nano-plating + intelligent mold repair, mold life increased by 10 times

● Conductive surface atomic reconstruction: EDM synchronously optimizes metal crystal phase, contact resistance drops by 40%

A global TOP3 connector factory 5G high-frequency terminal mold requires 0.12mm thick gold-plated contacts with a coplanarity of ≤0.003mm. The yield rate of traditional stamping is only 15%. We launched the multi-axis mixed gas EDM solution, achieved a yield rate of 99.9% in 36 hours, and won a supply chain order of 10 million yuan from a listed company!

From 0.03mm ultra-micro medical connectors to 800A high-voltage fast charging terminals, from 144-pin CPU sockets to Starlink satellite gold fingers, 8921 extreme cases roar: When traditional processes encounter a dead end in conductive technology, EDM stamping is the plasma lightsaber that opens a new era!