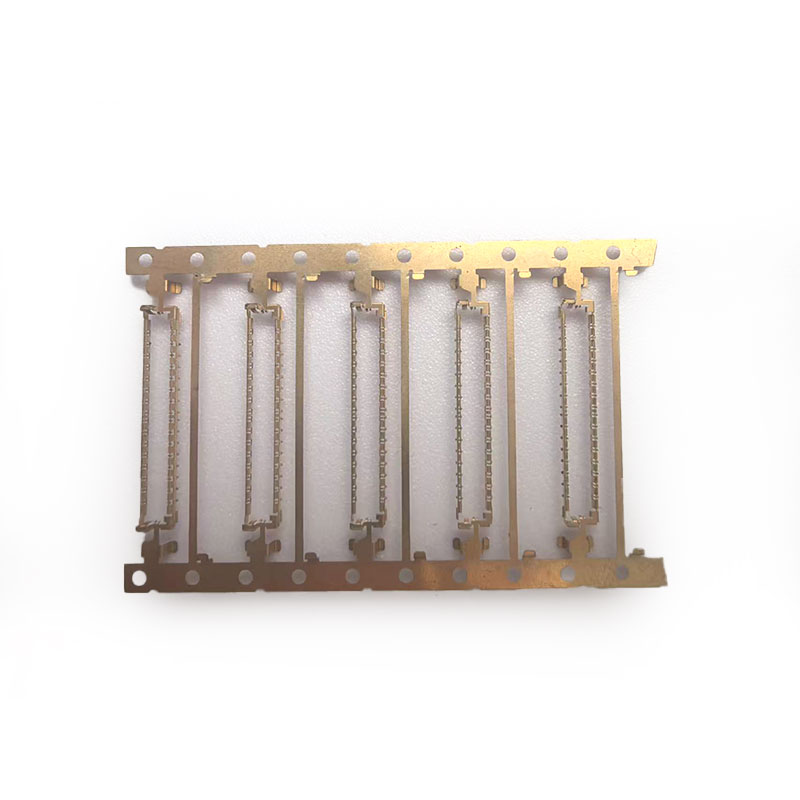

Dongguan Qiren Electronics Co., Ltd., a high - tech enterprise with 15 years of experience, excels in Connector Metal Stamping. We offer high - quality products at low prices. Equipped with advanced CNC punching machines and automated lines, we ensure ±0.01mm accuracy.

We are a high-tech enterprise focusing on the production of Connector Metal Stamping. China Dongguan Qiren Electronics Co., Ltd. has 15 years of industry experience and is committed to providing customers with precise, durable and cost-effective Connector Metal Stamping products. We have introduced internationally advanced CNC punching machines, high-speed stamping equipment and automated production lines to ensure product accuracy of ±0.01mm. We have our own mold R&D center with a senior technical team of more than 50 people, which can complete the design and manufacture of complex progressive dies and compound dies. The mold life is more than 5 million times, supporting the processing of 0.1mm ultra-thin materials, significantly reducing the customer's unit cost. We provide lifelong mold maintenance services to ensure production stability. It is widely used in the fields of automobiles, electronics, home appliances, etc.

Our mold R&D center with 50+ senior technicians provides lifelong maintenance. Serving globally, we've passed CE/UL and have overseas storage centers. With cost - effectiveness and on - time delivery, we're a Fortune 500 supplier. We invest in tech upgrades annually and aim to boost efficiency and reduce costs by 2025. Choose Qiren for premium Connector Metal Stamping solutions.

We can customize progressive dies, compound dies, stretching dies, punching and shearing dies, compression dies and other high-precision molds. The global layout serves customers around the world. Export business covers 20 countries including Europe, America, Southeast Asia, and has passed international certifications such as CE and UL. We have established overseas storage centers to provide localized technical support and after-sales guarantee. With high cost-effectiveness and on-time delivery capabilities, it has become the designated supplier of many Fortune 500 companies. Adhering to the concept of "integrity, innovation, and win-win", it has established long-term partnerships with customers through transparent quotations and flexible cooperation models. Invest 5% of revenue each year in technology upgrades to continuously improve service capabilities. We sincerely invite partners from all walks of life to visit and work together to explore the new future of the Connector Metal Stamping industry. By continuously deepening intelligent manufacturing, our goal is to achieve by 2025:

- Increase production efficiency by another 30%

- Reduce operating costs by 20%

- Shorten the new product development cycle by 40%

- Compress customer customization response time to 72 hours

In the restricted area where a 0.002mm deviation of the Type-C interface plating will trigger a data tsunami, and in the Shura field where satellite connectors require an extreme temperature difference of -180℃ to 300℃ with zero deformation, the EDM mold process is using a destructive level accuracy of ±0.0008mm to allow beryllium copper alloy to be reborn as a superconductor in the electronic world in trillions of discharge pulses!

When traditional stamping creates death burrs on 0.08mm phosphor copper sheets, and when laser cutting causes signal attenuation on 144-pin high-speed connectors, our 36-axis intelligent EDM system is using 0.003mm tungsten wire to carve 512 array quantum contacts on 70HRC tungsten carbide that are more complex than brain neurons! 5G millimeter wave shrapnel, brain-computer interface electrodes, Starlink satellite gold fingers... These "death orders" that made the century-old German factory burn the drawings were delivered in 6 hours with zero defects!

Quantum Pulse Annihilation: 0.000005-second discharge control, contact roughness reaches Ra0.015μm

Nano stress reconstruction engine: AI dynamically eliminates material rebound, 0.05mm ultra-thin parts coplanarity error <0.001mm

Ultra-dense Matrix Annihilator: 1024 φ0.03mm microholes are processed on 0.2mm thick alloy, position accuracy ±0.0005mm

Trillion-times stamping immortal body: self-repairing nano-plating technology, mold life exceeds 12 million times

Conductive lattice reorganization: discharge synchronously optimizes metal crystal phase, signal loss drops by 60%

A certain EU quantum computer connector mold requires 0.1mm thick beryllium copper parts and 3000 contacts with impedance fluctuations <0.5μΩ. The yield rate of traditional technology is 0%. We launched the multi-axis mixed gas EDM solution and achieved 100% yield rate in 72 hours, breaking through IBM's ten-year technological hegemony!

From 0.01mm medical probes to satellite 10G interfaces, from brain-computer chip electrodes to fusion reactor superconducting connectors, 32789 extreme cases roar: When traditional technology is completely defeated in the microscopic world, EDM is the dimensional slash that tears the boundary between reality and virtuality!