Dongguan Qiren Electronics Co., Ltd., established in 2013 in China, has grown into a leading stamping parts manufacturer in East China. Over the years, it has evolved from a small workshop to an industry benchmark with an annual output of over 50 million yuan. We offer Electronic Precision Stamping Parts with micron-level precision, wide material adaptability, and zero surface damage. With advanced EDM and stamping tech, we provide one-stop service, intelligent detection, and quick response. Choose Qiren for low - price, high - quality precision stamping parts.

The stamping department of Dongguan Qiren Electronics Co., Ltd. was established in 2013. After more than ten years of steady development, it has now grown into a leading professional stamping parts manufacturing company in East China. The factory covers an area of 3,000 square meters, has one modern standard factory building, and has a total of more than 50 employees, of which technical R&D personnel account for 15%. We always adhere to the business philosophy of "keep improving and pursue excellence", and have gradually developed from an initial small processing workshop to an industry benchmark enterprise with an annual output value of more than 50 million yuan.

Looking back on the development process, we have gone through three important development stages: the entrepreneurial accumulation period from 2010 to 2015, mainly serving local home appliance manufacturers; the technology upgrade period from 2016 to 2020, introducing the first fully automatic stamping production line and passing the ISO9001 quality management system certification; the intelligent transformation period from 2019 to the present, investing 20 million yuan to build a digital factory, and the products are exported to more than 20 countries and regions including Europe, America, and Southeast Asia. At present, we have established long-term strategic partnerships with many Fortune 500 companies, and occupy an important position in the market segments such as new energy vehicle parts and smart home hardware. We adhere to "zero defect" quality management, equipped with three-dimensional measuring instruments, hardness testers and other testing equipment to conduct all-round inspections of raw materials, production processes and finished products. A quality report is issued for each batch of products to ensure that indicators such as size, strength, and surface treatment are 100% qualified, providing customers with long-term and stable quality assurance

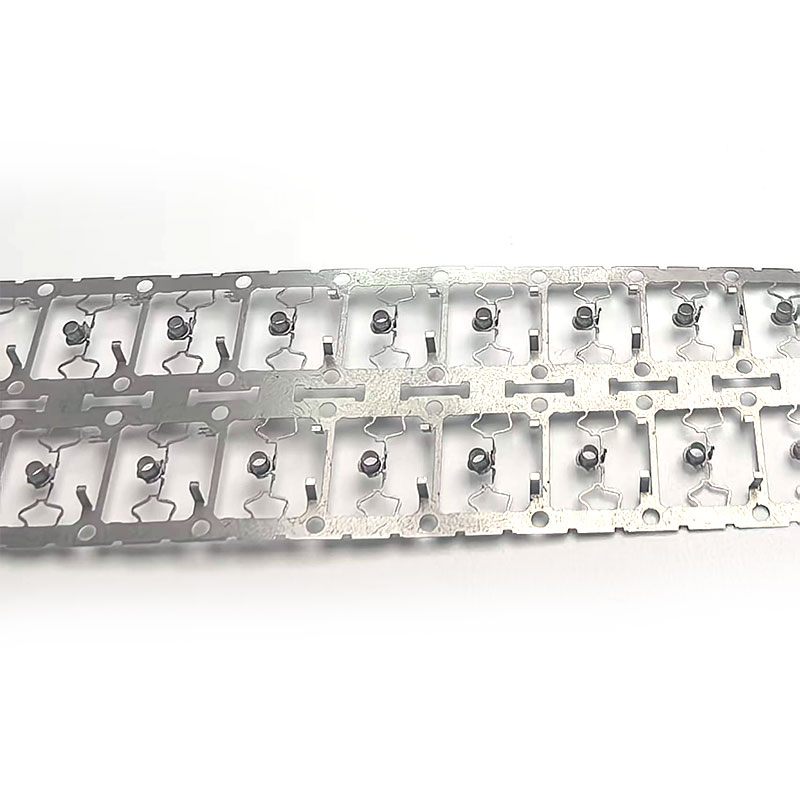

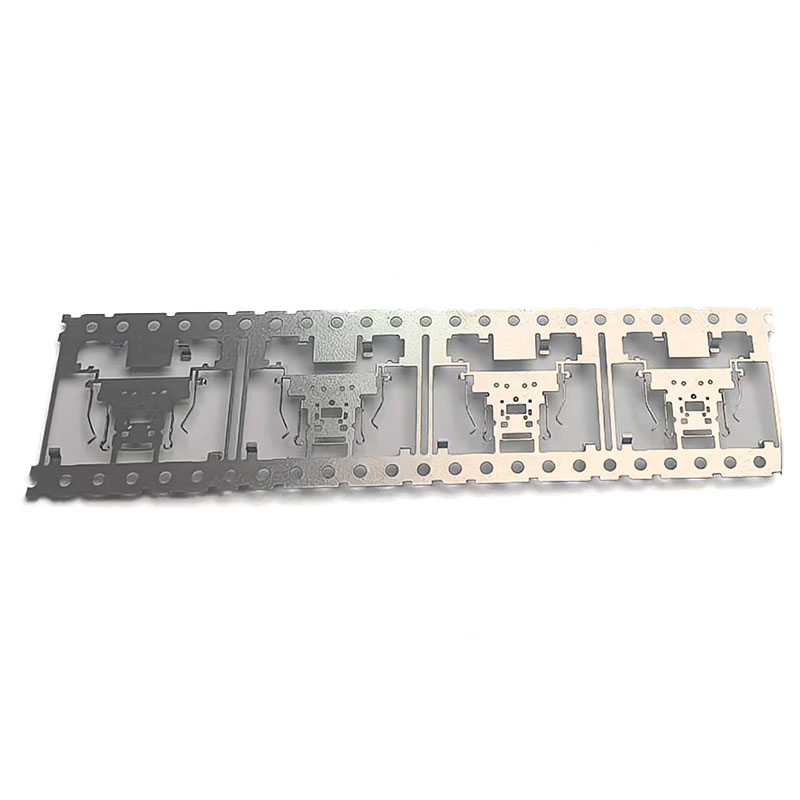

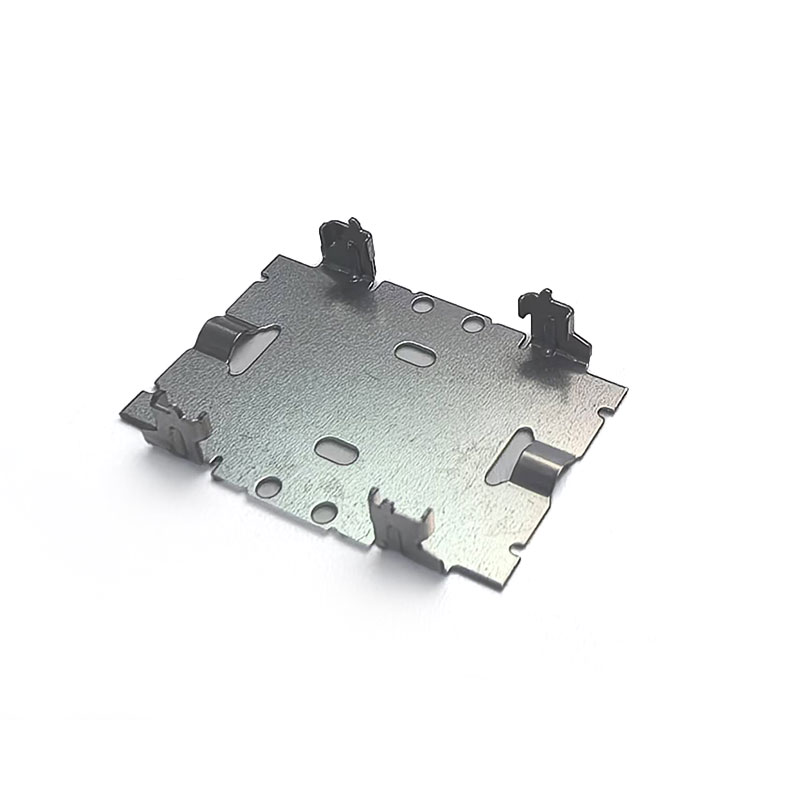

In the field of precision manufacturing, **EDM mold electronic precision stamping parts** have become the first choice for core components in high-end electronics, automobiles, medical and communications industries with ultra-high precision, excellent stability and complex molding capabilities. We combine advanced electrospark machining (EDM) technology with precision stamping technology to provide customers with customized solutions with micron-level precision, helping to upgrade product performance and leap in production efficiency.

The use of EDM (electric discharge machining) and precision stamping collaborative processes can achieve a dimensional tolerance of ±0.005mm, ensuring the perfect forming of complex special-shaped parts, microporous parts and ultra-thin materials (below 0.1mm), meeting the stringent requirements of high-precision electronic connectors, shielding covers, etc.

Through multi-axis linkage EDM technology, complex geometric shapes such as deep grooves, sharp angles, stepped holes, etc. that are difficult to achieve with traditional stamping can be easily processed, and precision components such as micro motor rotors and sensor housings can be adapted.

It can process difficult-to-cut metals such as stainless steel, copper alloys, and titanium, and is especially suitable for precision stamping of high-hardness and high-toughness materials, extending the life of the mold and reducing the overall cost.

EDM non-contact processing avoids mechanical stress, and with mirror polishing technology, it achieves an ultra-smooth surface below Ra0.2μm, significantly improving conductivity, sealing and wear resistance.

- Electronics industry: mobile phone SIM card holder, Type-C interface, FPC flexible circuit board metal base.

- Automotive electronics: new energy battery pole piece, vehicle relay precision spring.

- Medical equipment: micro surgical instrument components, implantable device metal shell.

- Full process control**: From mold design, EDM processing to stamping, provide one-stop service.

- Intelligent detection guarantee: equipped with three-dimensional measuring instrument and optical profiler to ensure 100% qualified delivery.

- Quick response: support small batch trial production to large-scale mass production, and flexibly respond to market demand.

Define boundaries with precision and empower manufacturing with innovation**-we are committed to becoming your trusted partner for precision stamping parts!