Dongguan Qiren Electronics, a leading China factory specializing in Hardware Connector Mold manufacturing, delivers ±0.01mm precision through CNC stamping and automated production. With 15+ years' expertise, Qiren provides durable, cost-effective progressive/compound/stretch molds for automotive, electronics, and smart home industries.

Dongguan Changan Qiren Electronics Co., Ltd. is a high-tech enterprise focusing on the manufacturing and production of hardware connector molds. It has 15 years of industry experience and is committed to providing customers with precise, durable and cost-effective hardware connector mold manufacturing products.

The introduction of international advanced CNC punching machines, high-speed stamping equipment and automated production lines ensures that the product accuracy reaches ±0.01mm. It is widely used in the fields of automobiles, electronics, home appliances, etc. It can customize a variety of high-precision molds such as progressive dies, compound dies, stretching dies, punching and shearing dies, compression dies, etc., and wins the trust of global customers with strict quality control.

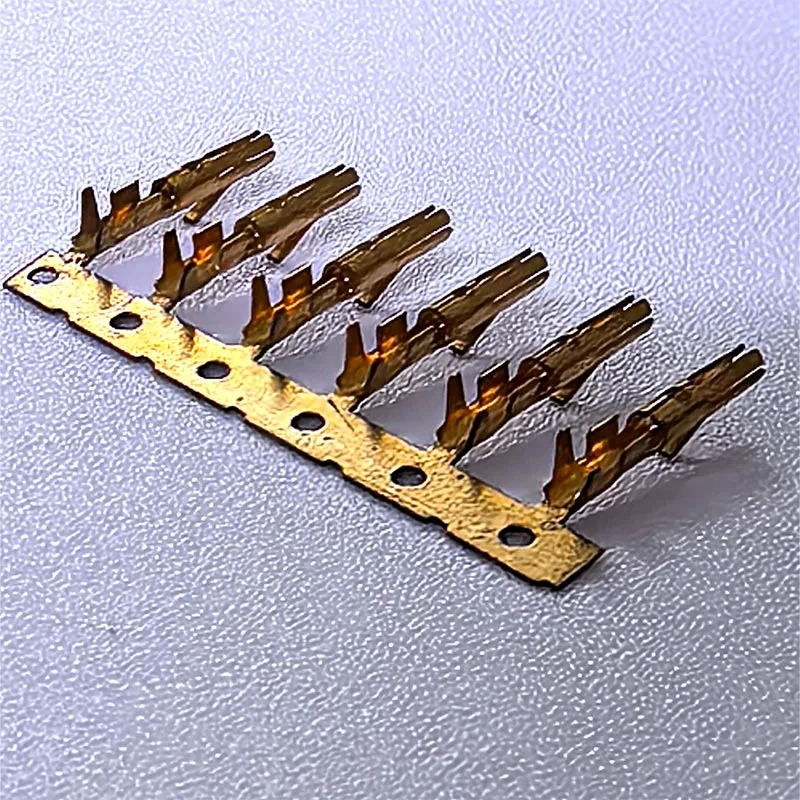

Hardware connector mold manufacturing refers to the process of processing metal materials (such as steel, copper, etc.) into molds that meet the structural and functional requirements of hardware connectors through process flows such as design, processing, assembly and debugging. As the core tool for the production of hardware connectors, molds directly affect the accuracy, quality and production efficiency of products.

1. Micron-level processing capabilities and complex structure molding

2. High-speed automated production and rapid mold change technology

3. Improved material utilization and long-term cost optimization

4. Consistency, stability and special performance support

5. Rapid response to market demand and intelligent digitalization

The entrepreneurial accumulation period from 2010 to 2015, mainly serving local home appliance manufacturers;

The technology upgrade period from 2016 to 2020, introduced the first fully automatic stamping production line, and passed the ISO9001 quality management system certification;

The intelligent transformation period from 2019 to the present, invested 20 million yuan to build a digital factory, and the products are exported to more than 20 countries and regions including Europe, America, Southeast Asia, etc.

At present, we have established long-term strategic partnerships with many Fortune 500 companies, and occupy an important position in the market segments such as new energy vehicle parts and smart home hardware.