China Qiren Electronics Co., Ltd., a factory and supplier, focuses on electronic, hardware, and mold manufacturing. It provides high - quality Hardware Plastic Mold solutions, covering design, production, and sales.

China Qiren Electronics Co., Ltd. is an enterprise focusing on electronic component manufacturing, Hardware Plastic Mold manufacturing and mold manufacturing. The company's business scope covers the design, production and sales of hardware and plastic molds, as well as the import and export of goods and technology, and is committed to providing customers with high-quality mold solutions.

The manufacturing process includes product design, mold processing, debugging, and maintenance. With efficient processing, material expertise, and design innovation, Qiren ensures quality. It aims to boost production efficiency, cut costs, shorten development cycles, and speed up customization responses by 2025.

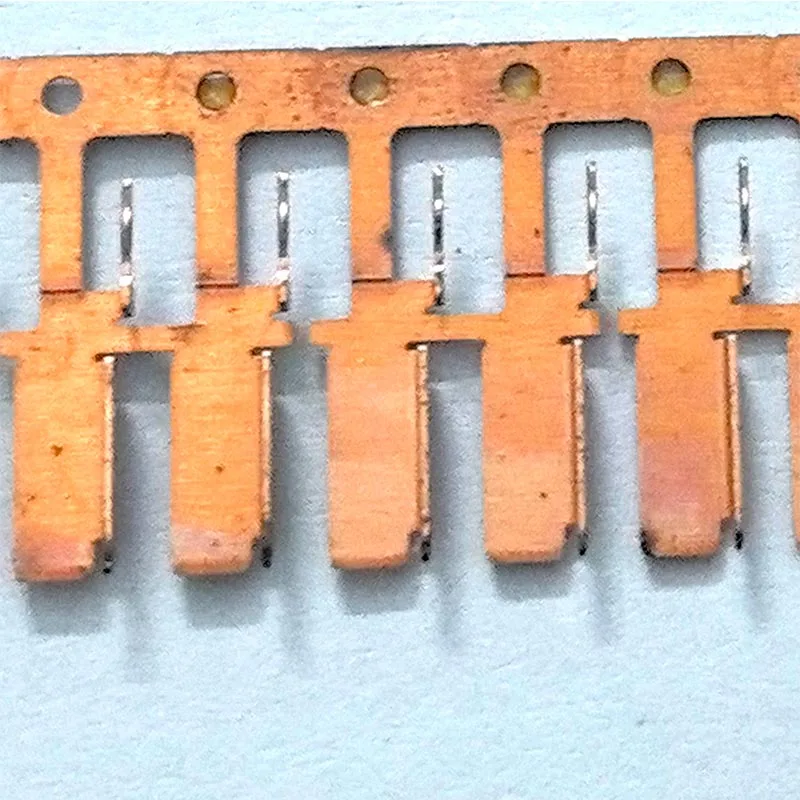

Hardware Plastic Molds are key tools for the production of metal and plastic parts in the manufacturing industry. Their manufacturing process includes product design, mold processing, debugging and other links. Hardware molds are mainly used to process metal materials to manufacture high-strength and durable parts, while plastic molds are used to manufacture plastic products, focusing on finish and surface quality.

1. Product design: Determine the product shape, size and material according to customer needs, design 3D drawings and mold structure.

2. Mold processing: Process the template and mold core through turning, milling, grinding and other processes to assemble into a complete mold.

3. Debugging and testing: Install the mold on the injection molding machine or punching machine for debugging to ensure that the opening and closing, injection molding and other performances meet the requirements.

4.Maintenance and optimization: Clean, lubricate and replace parts of the mold regularly, and make optimization adjustments based on production feedback.

1. Efficient processing capabilities

2. Material selection and durability

3. Design innovation and customization

Quality assurance: Adhering to the principle of "quality first, customer first", provide high-quality after-sales service.

Technical cooperation: Establish long-term cooperative relations with customers, optimize mold design based on feedback, and improve production efficiency.

- Increase production efficiency by another 30%

- Reduce operating costs by 20%

- Shorten the development cycle of new products by 40%

- Compress the response time for customer customization to 72 hours