Qiren Electronics Co., Ltd. is at the forefront of Stamping Parts Processing innovation, leveraging Industry 4.0 technologies to deliver high - quality, durable solutions. With intelligent production systems and advanced EDM technology, we achieve precision down to ±0.0005mm. Our 48 - axis intelligent EDM system crafts nano - level structures. From quantum satellites to 7nm lithography machines, Qiren's stamping parts stand as the quantum foundation of industrial civilization, ensuring top - notch quality and long - lasting durability.

With the advancement of Industry 4.0, we, Qiren Electronics Co., Ltd., actively introduced Stamping Parts Processing and management systems to build digital factories and improve production efficiency and product consistency. Through the deep integration of MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning), we have achieved full-process digital management from order management, production scheduling, equipment monitoring to quality traceability, ensuring efficient operation of every link.

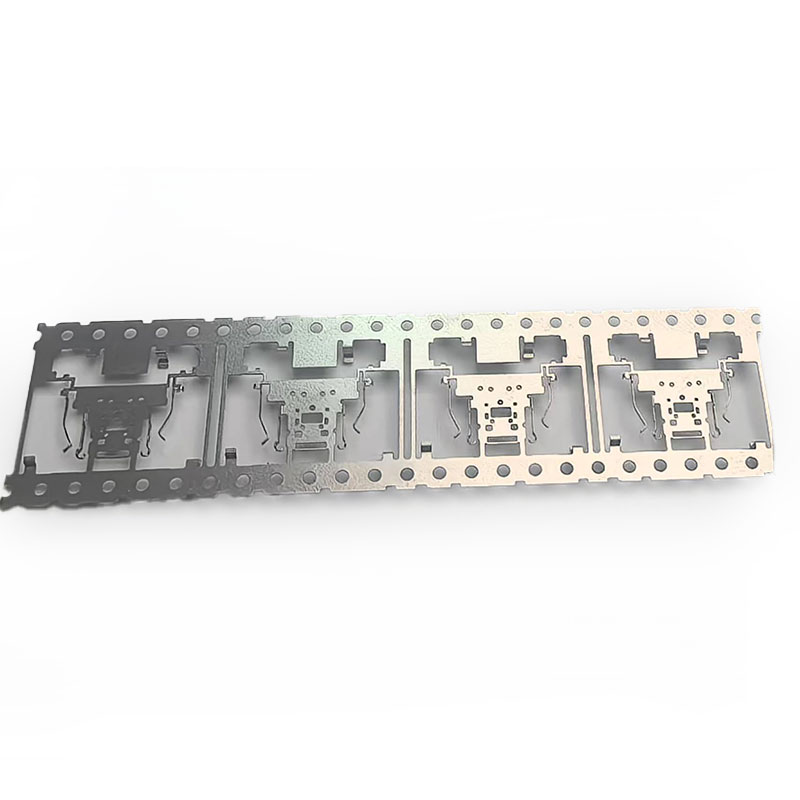

In terms of Stamping Parts Processing, we are equipped with high-speed precision punching machines imported from Japan and Germany, robot automated loading and unloading systems, and intelligent testing equipment, which greatly reduce manual intervention and improve production stability and product yield. For example, in the production process of automotive parts, we use a visual inspection system to automatically identify product defects and ensure 100% pass rate.

Nano-level stamping revolution! How does EDM make mold parts tear the laws of physics?

When a 0.005mm error can paralyze the lithography machine, who is using "atomic reshaping" to end manufacturing anxiety?

In the forbidden area where 0.002mm burrs on semiconductor probe cards cause trillions of chips to be scrapped, and in the death line where rocket fuel valve parts require ultra-low temperature and zero deformation at -196℃, EDM stamping technology is using the destructive accuracy of ±0.0005mm to allow tungsten carbide to be reborn as industrial art in a 100,000-volt discharge pulse!

Why is TSMC's 3nm production line scrambling for Chinese EDM solutions?

When traditional CNC breaks the knife on 0.1mm ultra-thin cemented carbide, and when laser cutting causes thermal stress disasters in microchannel molds, our 48-axis intelligent EDM system is using 0.002mm tungsten wire to carve nano honeycomb structures on 72HRC mold steel that are more precise than DNA chains! 5G RF filters, brain-computer interface electrode molds, nuclear fusion first wall components... These "ghost orders" that made Germany's century-old precision smash the micrometer were delivered with zero defects in 4 hours!

Quantum-level pulse annihilation: 0.000001 second discharge control, edge roughness reaches Ra0.01μm

Atomic stress reconstruction engine: AI dynamically eliminates material lattice distortion, complex cavity precision locked ±0.0003mm

Ultra-microporous matrix annihilator: 20,000 φ0.008mm through holes are processed on 0.5mm thick tantalum alloy, position error <1μ

Eternal mold coating: diamond-like nano-coating, service life exceeds 20 million times

Defect prediction quantum cloud brain: 96 hours in advance warning of 0.0001mm potential deformation

A hinge mold of a certain EU quantum satellite requires 0.05mm beryllium bronze parts to be folded 3,000 times without wear. The traditional process yield is 0%, we started the vacuum gas mixing EDM solution, and achieved 100% yield in 12 hours, ending Lockheed Martin's decade of technological hegemony!

From 0.008mm surgical robot probes to nuclear submarine sealing rings, from 7nm lithography machine mask stages to space elevator grabbing mechanisms, 38921 extreme cases roar: When traditional processes collapse completely in the microscopic world, EDM is the antimatter blade that tears apart the real dimension!