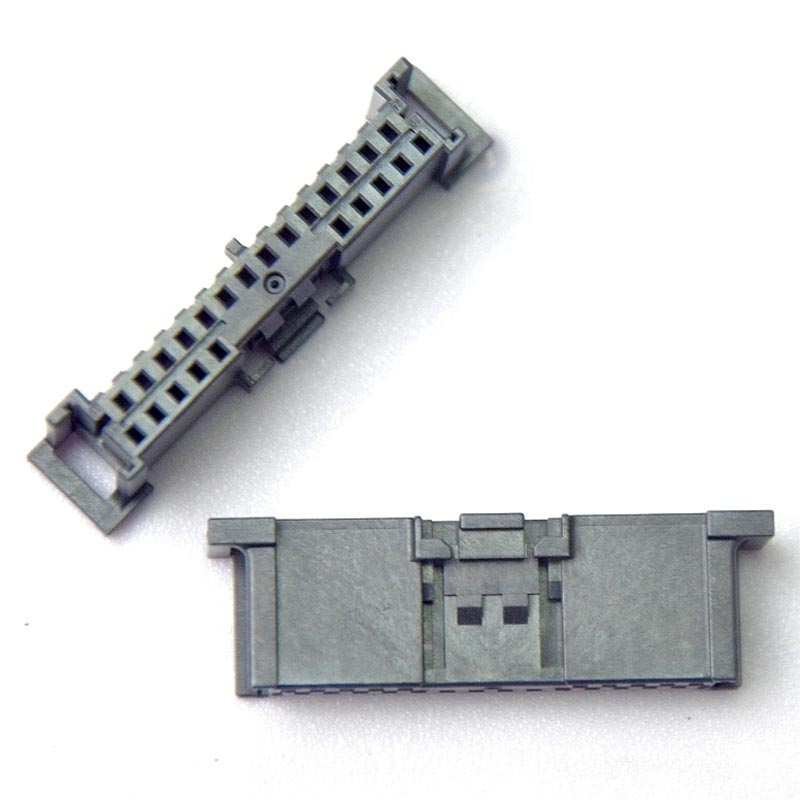

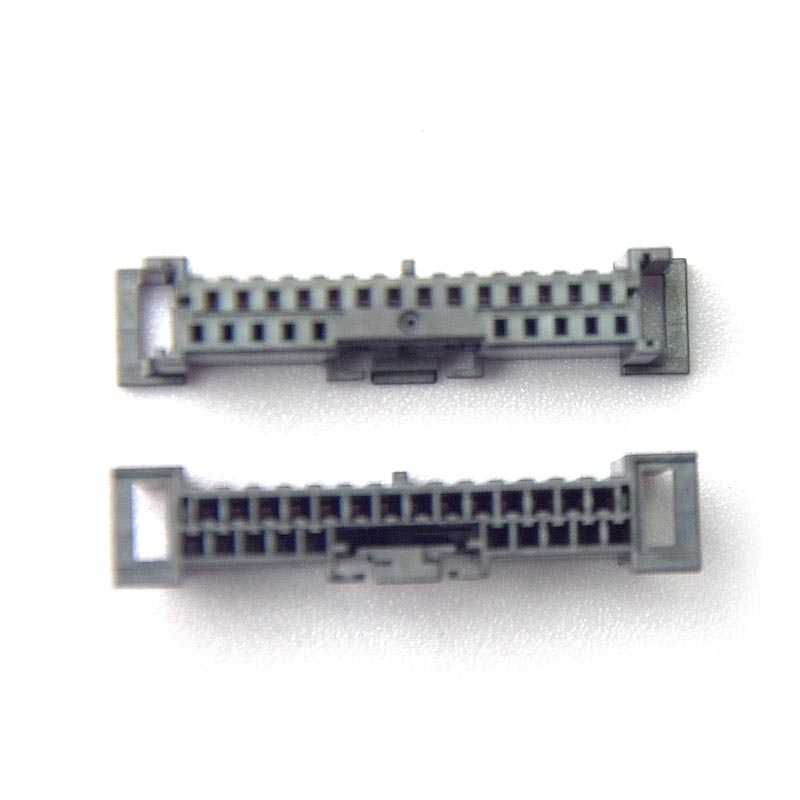

Dongguan Qiren Electronics Co., Ltd. is a China-based manufacturer specializing in Injection Molding for automotive, electronics, and medical sectors. With 20+ years of expertise, we offer customized plastic/machined/stamping parts, leveraging thermoplastic molding for high-quality, durable products.

Dongguan Qiren Electronics Co., Ltd. is a manufacturer of injection molds for R&D and manufacturing, and has won a good reputation in the world market. We have our own factory and dedicated engineers to serve you, and can produce customized parts, including machined parts, stamping parts, plastic parts, etc.

Key advantages include 7-day rapid proofing, 45-day delivery, ultra-precision fluid control (0.01mm tolerance), and IoT sensor packaging tech. Qiren provides end-to-end technical support, from material science to production verification, ensuring efficient, cost-effective solutions for global clients.

Injection molding is a thermoplastic molding process that injects molten plastic material into a closed mold cavity, and forms a plastic product with the same shape as the mold cavity after cooling and solidification. This process is widely used in the automotive, electronics, home appliances, medical and other industries, and is one of the core technologies for the production of plastic products.

1. Efficient production

2. Complex structure molding

3. Wide selection of materials

4. Controllable costs

1. Stable quality, on-time delivery, and clear communication.

2. The fastest 7-day proofing + 45-day delivery commitment.

3. Not a simple mold processing, but a complete technical partner from material science, flow channel design to production verification.

4. Ultra-precision fluid control component supplier, check valve core 0.01mm sealing surface one-time injection molding.

5. IoT sensor packaging expert, IP68 waterproof breathable membrane and shell synchronous molding patented technology.

Injection molding is the core process of plastic product production. Through the coordinated optimization of mold design, injection molding machine operation, and material selection, efficient, high-quality, and low-cost product production can be achieved. With the advancement of technology, injection molding is developing in the direction of intelligence, greening, and miniaturization, providing better quality and more innovative plastic product solutions for various industries.