Qiren is a clothing manufacturer focusing on Automotive Injection Molding. As the professional manufacture, we would like to provide you Automotive Injection Molding. And we will offer you the best after-sale service and timely delivery.

China Qiren Electronics is able to provide you with customized high-quality automotive injection molding, plastic molds, with tailor-made design and mold development, enabling customers to create unique products that meet their specific needs and preferences, including customized sizes and colors.

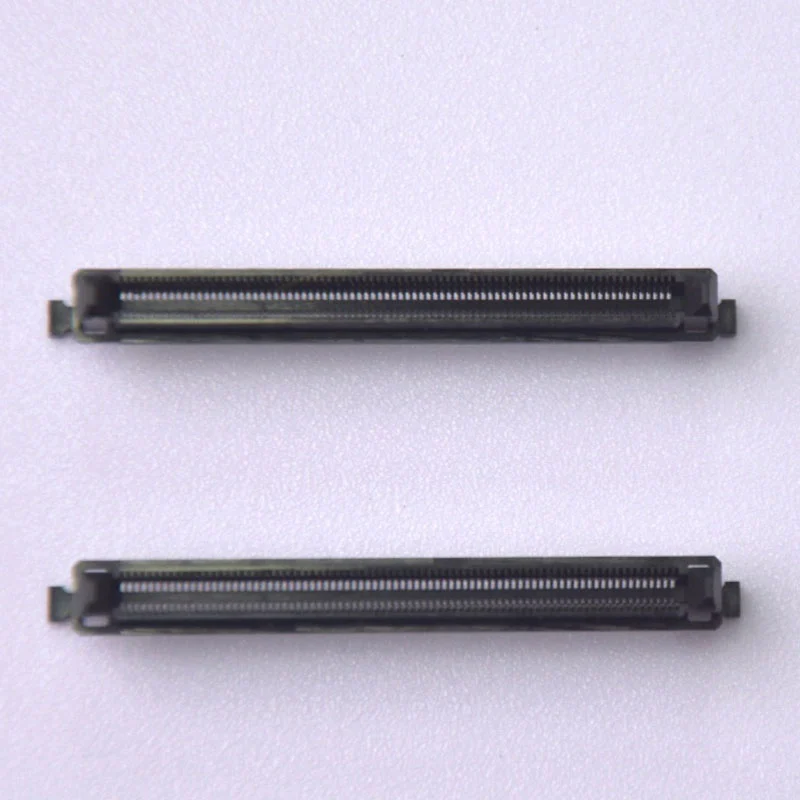

High-precision automotive injection molding and quality assurance: Our automotive injection molding process enables us to produce high-precision products with complex designs and details. Accurate molding and quality control of custom injection molded parts, from raw material procurement to finished product factory inspection, ensure high precision, long life and low maintenance of molds.

Qiren Electronics' automotive injection molding molds are designed and manufactured using the latest CNC technology and ProE software to ensure precision and accuracy in every detail.

1. Our automotive injection molding parts are made of a variety of high-quality materials, including PC, LCP, ABS, POM, PP, POK, PBT, PA9T, PA6 ,PA66PET, PC+ABS, etc., to ensure durability and resistance to various environmental conditions.

2. "Japanese JIS standard certified mold manufacturer, 20 years of deep cultivation of high-precision plastic connector molds, ±0.01mm tolerance has won unanimous praise from customers."

3. "Automotive functional parts mold supplier, automotive injection molding, multi-slide linkage mold technology to achieve integrated molding of automotive ECU shells.

4. "Industrial 4.0 mold workshop, all equipment integrated with MES system, real-time monitoring of mold wear status predictive maintenance. "

1. Each set of molds must undergo 3 rounds of mold trials before production to ensure that it is consistent with the delivery standards required by customers.

2. Reject the unspoken rules of the mold industry, and the contract clearly marks the steel brand and heat treatment process parameters of key components.

3. Engineer culture driven, direct connection with technical teams with more than 15 years of experience, to eliminate technical distortions relayed by sales.

4. Transparent cost accounting system, mold quotation includes all hidden costs, and there is no subsequent additional fees.

5. Continuous improvement plan, providing optimization and upgrade services for the first year of mold use.

6. Global quality unified standards, export molds and domestic deliverables use exactly the same quality inspection process.

7. Technical confidentiality firewall, independent encryption server storage drawings, physical isolation of confidential project workshops.

8. Green manufacturing practitioner, 100% recycling of all waste materials, photovoltaic power supply in the factory to reduce carbon footprint.