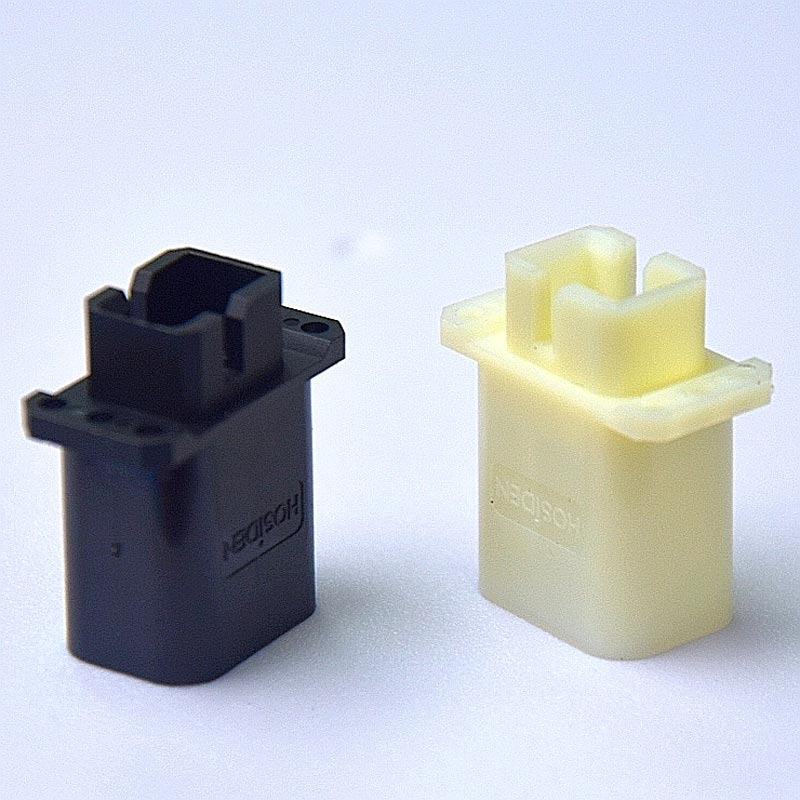

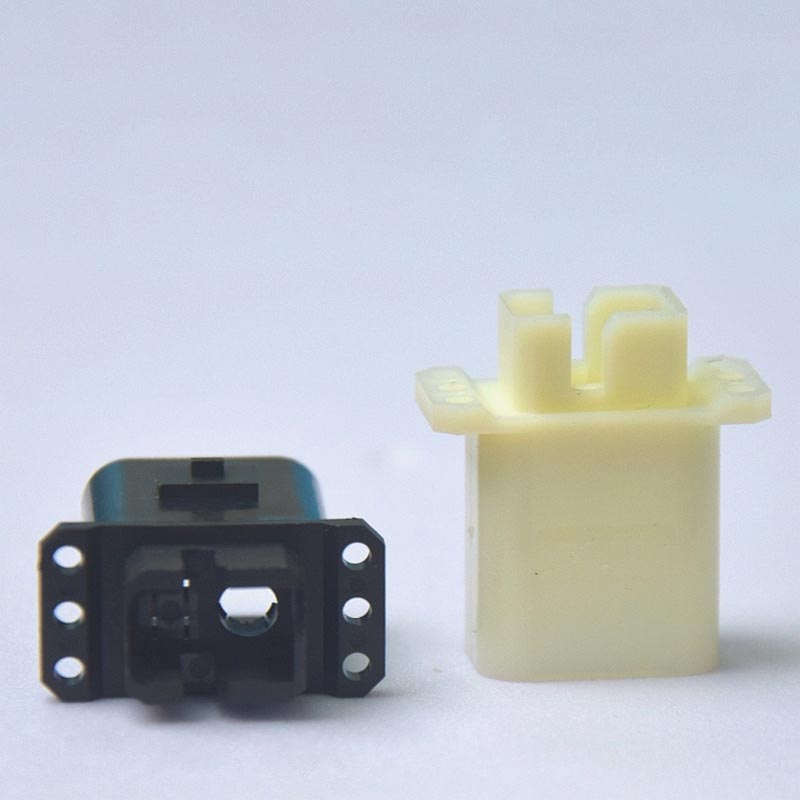

China Qiren, a leading OEM manufacturer in microelectronics, excels in Injection Molding Automation, exporting to Europe, America, and Southeast Asia. With 15+ years of technical expertise, Qiren offers transparent cost accounting, eliminating hidden fees, and ensures product quality through advanced automation.

As an enterprise in the field of microelectronics manufacturing in China, China Qiren has become a strategic partner of world-renowned brands with its innovative breakthroughs in injection molding automation technology, and its products are exported to markets such as Europe, America, and Southeast Asia.

Direct connection with technical teams with more than 15 years of experience, eliminating technical distortion of sales retelling, transparent cost accounting system, mold quotation includes all hidden costs, no subsequent additional costs, rejecting the unspoken rules of the mold industry, and the contract clearly marks the steel brand and heat treatment process parameters of key components, technical confidentiality firewall, independent encryption server storage drawings, and physical isolation of confidential project workshops.

Key advantages include improved efficiency, reduced costs, and strict quality control. As an Industry 4.0 pioneer, Qiren integrates AI and digital twins for intelligent, flexible, and eco-friendly solutions. Choose Qiren for high-quality, durable injection molding automation.

Injection molding automation refers to the process system that integrates mechanical, electronic, and computer technologies to achieve unmanned or semi-unmanned operation of the entire injection molding production process (raw material processing, injection molding, post-processing, quality inspection, and packaging) to improve production efficiency, reduce labor costs, and ensure product quality.

1. Improved efficiency

2. Reduced costs

3. Quality assurance

1. Leading technology

2. Quality assurance

3. Worry-free service

Injection molding automation is a typical application of Industry 4.0 in the field of plastic processing. Through the deep integration of mechanical, electronic and computer technologies, it achieves comprehensive optimization of production efficiency, quality and cost. With the further development of technologies such as AI and digital twins, injection molding automation will accelerate its evolution towards intelligence, flexibility and greenness.