China Qiren, a professional factory specializing in High-Precision Hardware Mold Processing, delivers ±0.01mm accuracy with 5M+ cycle lifespan molds. Equipped with CNC/high-speed stamping lines, Qiren’s 30+ engineer team designs progressive/compound dies for automotive, electronics, and medical industries. CE/UL-certified and ISO-compliant, Qiren reduces unit costs by 40% through 0.1mm ultra-thin material processing and overseas warehousing.

China Qiren Electronics is a high-tech enterprise focusing on high-precision hardware mold processing. With 15 years of industry experience, it is committed to providing customers with precise, durable and cost-effective stamping products. The company has introduced internationally advanced CNC punching machines, high-speed stamping equipment and automated production lines to ensure product accuracy of ±0.01mm. It has its own mold R&D center and a 30-person senior technical team to complete the design and manufacture of complex progressive molds and compound molds.

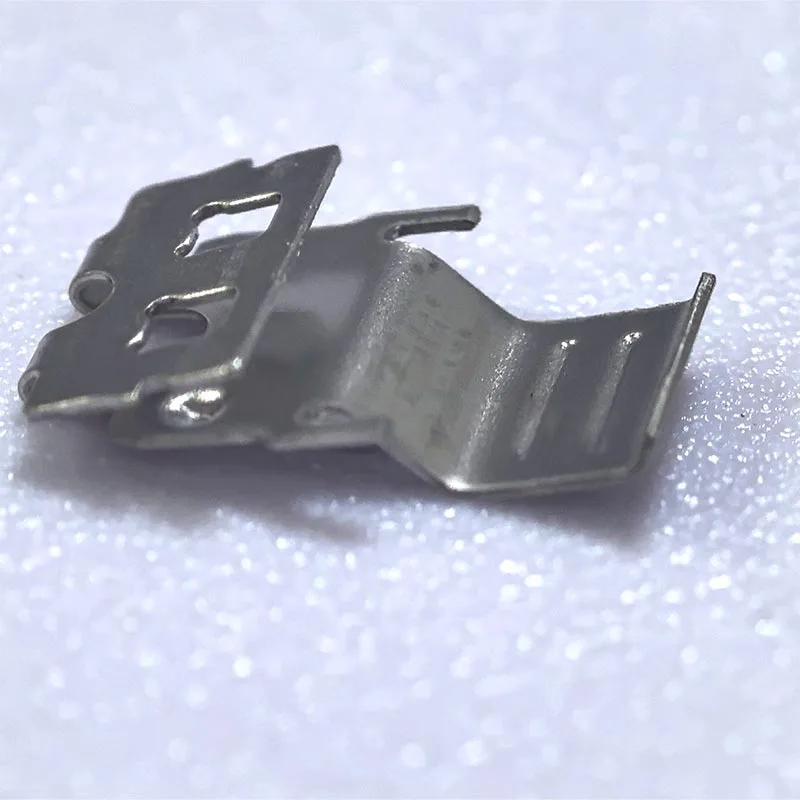

High-precision hardware mold processing is a precision manufacturing process that involves the use of advanced technology and equipment to produce hardware molds with extremely high dimensional accuracy and shape accuracy.

1. Extreme processing accuracy

2. Excellent production efficiency

3. Ultra-long mold life

4. Extremely high material utilization

5. Perfect surface quality

6. Strong customization capabilities

7. Integration of advanced technologies

8. Significant cost control

1. Our mold life is more than 5 million times, supporting 0.1mm ultra-thin material processing, significantly reducing customers' unit cost.

2. Provide lifelong mold maintenance services to ensure production stability.

3. Widely used in the fields of automobiles, electronics, home appliances, etc., it can customize a variety of high-precision molds such as progressive dies, compound dies, stretching dies, punching and shearing dies, compression dies, etc. Global layout.

4. Serving customers around the world, export business covers 20 countries including Europe, America, Southeast Asia, etc.

5. Passed international certifications such as CE and UL.

6. Set up overseas storage centers to provide localized technical support and after-sales guarantee.

7. With high cost-effectiveness and on-time delivery capabilities, it has become a designated supplier for many Fortune 500 companies. Adhere to the concept of "integrity, innovation, and win-win", and establish long-term partnerships with customers through transparent quotations and flexible cooperation models.