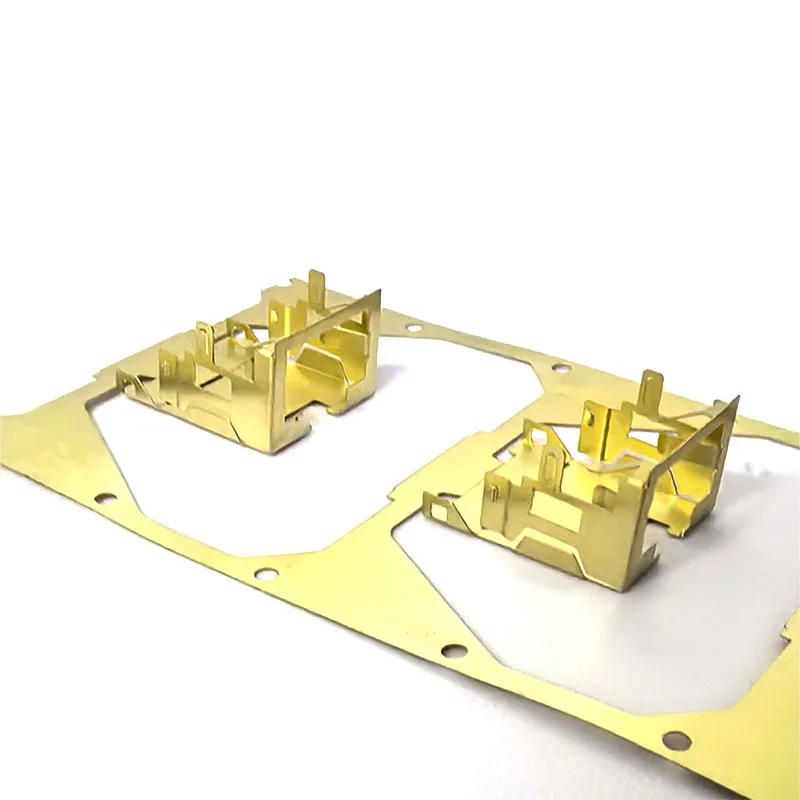

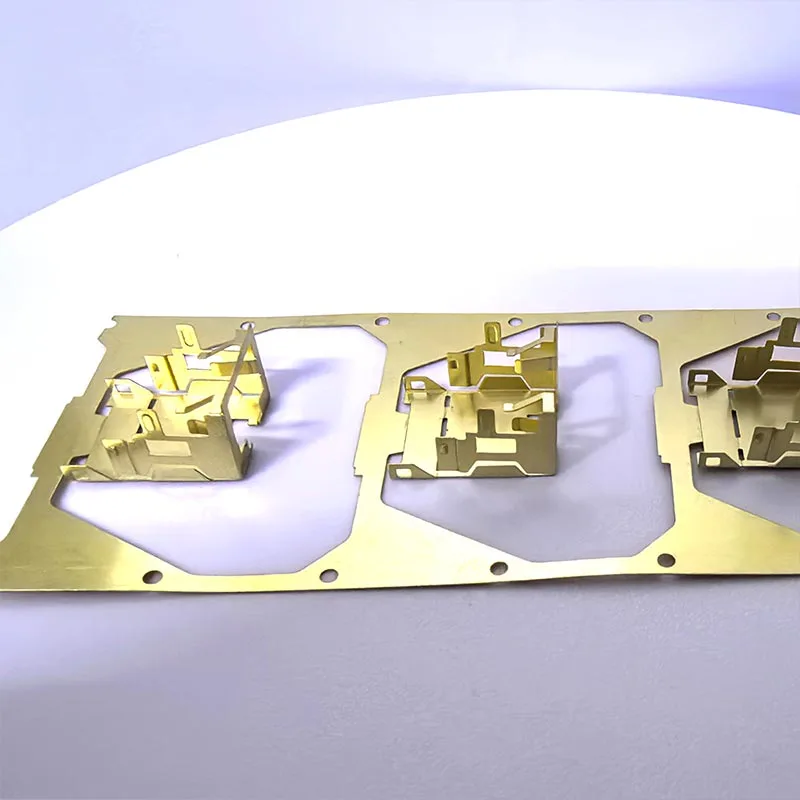

Dongguan Qiren Electronics, a leading China manufacturer of high-quality, durable Hardware Stamping Mold, delivers ±0.01mm precision solutions for automotive, medical, and electronics industries. With Fortune 500 partnerships, Qiren’s ISO-certified molds combine 5M+ lifespan, AI-driven MES systems, and robotic automation to reduce costs by 30% while ensuring zero-defect outputs. Specializing in progressive/stretch/compound dies,

Dongguan Qiren Electronics Co., Ltd. is a leading manufacturer of Hardware Stamping Mold in China, headquartered in Chang'an Town, Dongguan City, Guangdong Province. As a high-tech enterprise, it focuses on the research and development, production and sales of high-precision metal stamping dies, serving multiple fields such as automobiles, electronics, home appliances, and medical care.

At present, we have established long-term strategic partnerships with many Fortune 500 companies, and occupy an important position in the market segments such as new energy vehicle parts and smart home hardware.

Qiren Electronics adheres to the "zero defect" quality management, equipped with three-dimensional measuring instruments, hardness testing machines and other testing equipment, and conducts all-round inspections of raw materials, production processes, and finished products. Each batch of Hardware Stamping Mold products is issued with a quality report to ensure that the indicators such as size, strength, and surface treatment are 100% qualified, providing customers with long-term and stable quality assurance.

1. Efficient production and precise molding

2. Material utilization and cost advantages

3. Product performance and quality assurance

4. Flexibility and applicability

5. Environmental protection and safety advantages

6. Wide range of industry applications

1. Professional R&D team

2. High-quality mold manufacturing

3. Customized services

4. Multiple material options

5. Competitive prices

6. Fast delivery

7. Quality assurance

With the advantages of high efficiency, precision and economy, Hardware Stamping Molds have become the core technology of modern manufacturing, especially in the fields of lightweight automobiles and miniaturization of electronic products. We sincerely invite partners from all walks of life to visit us and work together to open up a new future for the metal stamping industry.