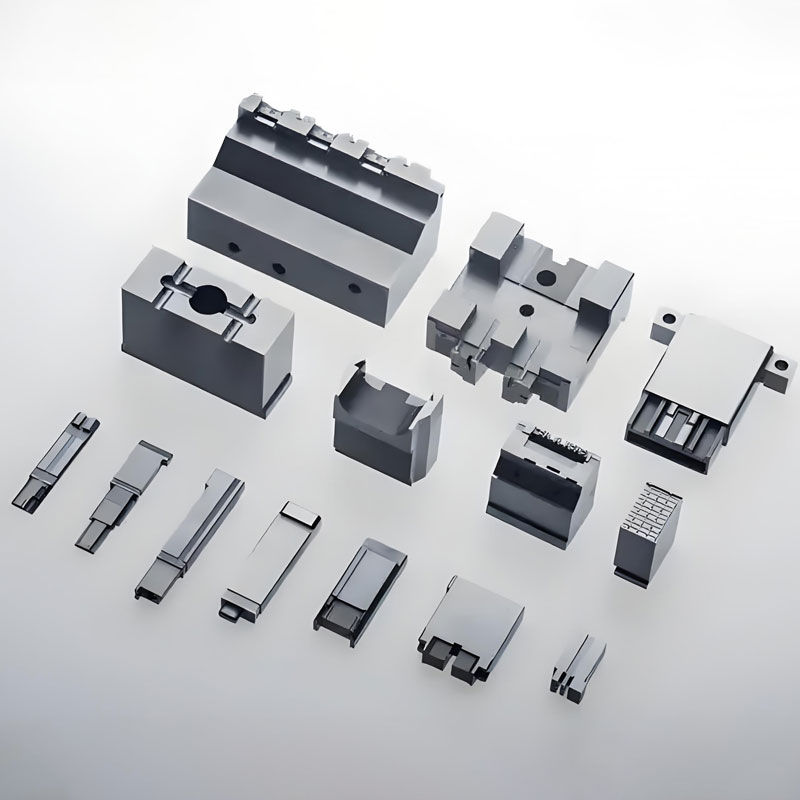

Dongguan Qiren Electronics delivers high-quality, durable Grinding Machine Precision Parts Processing, achieving ±0.001mm tolerance and Ra≤0.01μm mirror finishes for industries like aerospace and automotive. Leveraging 20+ years’ expertise, Qiren’s 5-axis CNC grinders and magnetic suspension spindle technology enable nano-level precision on hardened steel (SKD61, tungsten steel), micro-nozzles (0.3mm), and semiconductor molds.

The processing department of Dongguan Qiren Electronics Co., Ltd. is an engineer and technical team with more than 20 years of industry experience, covering mold design, Grinding Machine Precision Parts Processing, EDM discharge machining, FG grinding, injection molding and other fields. The factory is equipped with 5 precision grinders. The grinding process is the core link of precision parts processing, especially good at achieving submicron accuracy and nanometer surface finish. Through surface grinders, internal and external cylindrical grinders, coordinate grinders and other equipment, materials such as cemented carbide, ceramics, and hardened steel can be fine-processed, and the tolerance control reaches ±0.001mm, meeting the ultimate requirements of high-precision parts such as optical lenses, semiconductor molds, and hydraulic valve cores.

With the integration of Grinding Machine Precision Parts Processing and automation technology, the efficiency of large-scale precision parts processing has been greatly improved. For example, the use of a double-station vertical grinder with a robot loading and unloading system can simultaneously complete the grinding wheel dressing and workpiece inspection during the processing process, and the processing time of a single piece can be shortened by more than 30%. For high-strength gears and transmission shafts in the automotive industry, precision creep-feed grinding technology optimizes the porosity of the grinding wheel and the tool speed to achieve efficient deep groove processing of more than 100 mm per minute, while maintaining a tooth profile error of 0.005 mm. Intelligent grinders can also analyze grinding vibration signals through AI algorithms, predict the life of the grinding wheel and automatically adjust parameters to stabilize the yield rate at more than 99.5%. High-end grinders break through the limitations of traditional processing and can complete the precision molding of ultra-complex structures such as micro grooves and special-shaped surfaces.

Using a five-axis linkage precision grinder, combined with magnetic suspension spindle technology, a micro-correction of three-dimensional surfaces can be achieved with a resolution of 0.1 μm, solving the problem of sub-millimeter feature processing of workpieces such as precision mold inserts and microfluidic chips. For example, when processing a micro nozzle with a diameter of 0.3 mm, a regular texture of 0.05 μm can be formed on the surface through the combination of a high-frequency oscillating grinding wheel and an air-floating guide rail, significantly improving the efficiency of fuel injection. Such process breakthroughs make grinders a key solution to the "bottleneck" link of precision manufacturing. Modern Grinding Machine Precision Parts Processing are equipped with online detection and temperature compensation systems to correct the grinding path in real time to ensure the dimensional consistency of complex curved surfaces. For example, when batch processing precision bearing raceways, the grinder can not only eliminate the residual stress of the previous process, but also achieve high repeatability through fine grinding wheel dressing technology, significantly improving product life and reliability. For superhard materials (such as SKD61, tungsten steel), it ensures long-term processing stability, supports drawings, samples, 3D scanning reverse engineering, and provides one-stop services from small batch trial production to large-scale mass production. Provides sandblasting (#400-#2000), hard anodizing, chemical nickel plating, vacuum coating, laser etching and other surface treatments to meet the needs of wear resistance, anti-static, matte, etc. Mirror polishing can reach #A1 level (Ra≤0.01μm), which meets the high-gloss requirements of automotive interiors, cosmetic packaging, etc. The design team uses UG, Pro/E and other software for mold flow analysis (Moldflow), predicts defects such as shrinkage and pores in advance, and optimizes the pouring system and cooling channel layout.

Through standardized mold base and insert design, we can reduce customers' manufacturing costs by 15%-30% and extend the mold life to more than one million times!