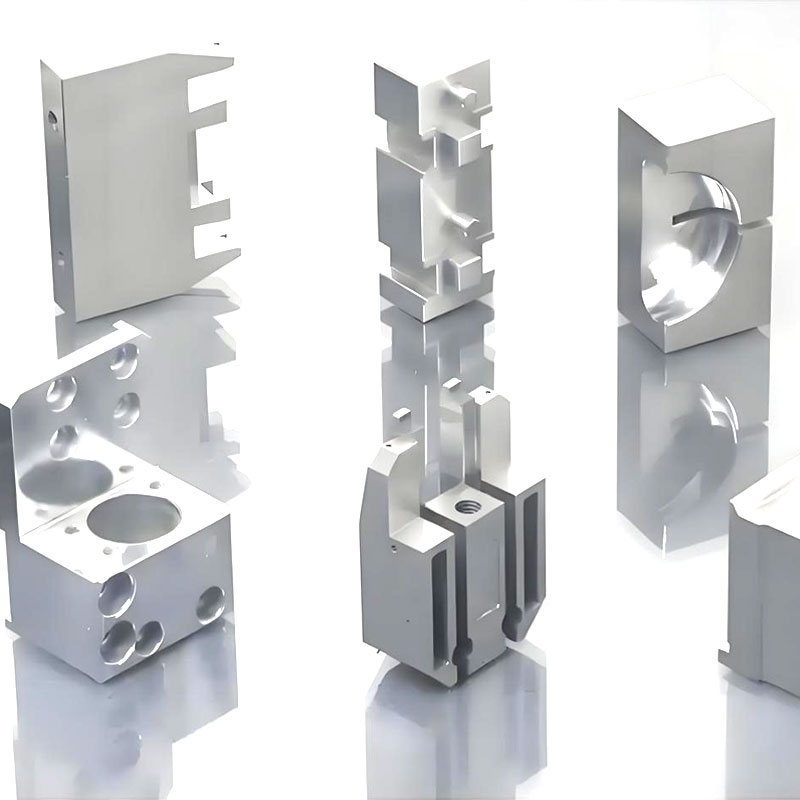

Dongguan Qiren Electronics excels in high-quality, durable Cnc Parts Processing, delivering micron-level precision (±0.001mm) for aerospace, automotive, and medical industries. With 20+ years’ expertise, Qiren’s 5-axis CNC and EDM-CNC hybrid technology process 60HRC tungsten steel, titanium alloys, and composites, achieving complex geometries like 0.08mm ribs and deep grooves. Trust this low-price provider for Cnc Parts Processing with material adaptability (aluminum, plastics) and million-cycle lifespan tooling.

Dongguan Qiren Electronics Co., Ltd. is an engineer and technical team with more than 20 years of experience in the parts processing industry, covering mold design, Cnc Parts Processing, EDM discharge machining, FG grinding, injection molding and other fields. Provide full-process technical support from drawing optimization to mass production. Whether it is a complex structure mold or a high-precision part, we can rely on rich practical experience to ensure quality and efficiency

Cnc Parts Processing technology uses computers to accurately control machine tools to achieve micron-level processing accuracy, which is suitable for high-demand fields such as aerospace and medical equipment. Automated programming and multi-axis linkage technology can quickly complete the processing of complex curved parts, reduce manual errors, improve production efficiency, and ensure the consistency of batch products.

With the help of five-axis linkage CNC equipment, precision processing of multi-angles, deep holes and special-shaped structures can be completed at one time, avoiding the loss of precision caused by multiple clamping. It is suitable for complex workpieces such as automotive engine parts and optical instruments, shortening the production cycle and reducing the overall cost.

CNC technology supports efficient processing of metals (aluminum, titanium alloys), engineering plastics and composite materials. It combines customized tools and cutting parameters to ensure the surface finish and dimensional stability of different materials, and meet the stringent performance requirements of parts in the electronics, semiconductor and other industries.

From 3D modeling to intelligent programming, CNC parts processing relies on digital systems to achieve full-process monitoring and real-time correction of processing errors. Combined with precision testing equipment, it ensures that each finished product meets ISO standards and provides traceable quality assurance for high-end manufacturing.

CNC technology is compatible with small-batch customization and large-volume orders, and responds flexibly to customer needs through fast tool change and modular design. It is especially suitable for R&D trial production, precision molds and other scenarios, and helps product iteration and innovation upgrades with high cost performance.

When CNC cutters frequently break on 60HRC tungsten steel, and when ordinary EDM takes twice as long to process deep grooves, our live cutting technology is using nano-level discharge pulse hybrid multi-axis milling on aviation titanium alloy to carve out 0.08mm reinforcing ribs thinner than a cicada's wing! Supercar engine block molds, folding screen shaft modules, artificial joint casting molds... These "forbidden zone challenges" that Japan Seiki is helpless against can now be delivered in 72 hours without repair!

When precision and efficiency must be achieved at the same time, EDM-CNC composite processing is the sharp blade that opens a new era of industry.