As a core tool in industrial manufacturing, hardware molds have deeply penetrated multiple fields such as automotive, electronics, and home appliances, becoming a key guarantee for mass-producing precision parts.

In the automotive manufacturing sector, hardware molds are responsible for processing core components of vehicle bodies. Door frames are formed in one go using large stamping dies, with dimensional errors controlled within 0.5mm to ensure assembly tightness; the fin dies in the engine compartment adopt a multi-station continuous stamping design, capable of processing 80 pieces per minute to meet automobile mass production needs. The battery casings of new energy vehicles rely on drawing dies to process 0.8mm-thick aluminum alloy sheets into complex cavity structures, ensuring the safety protection of battery packs.

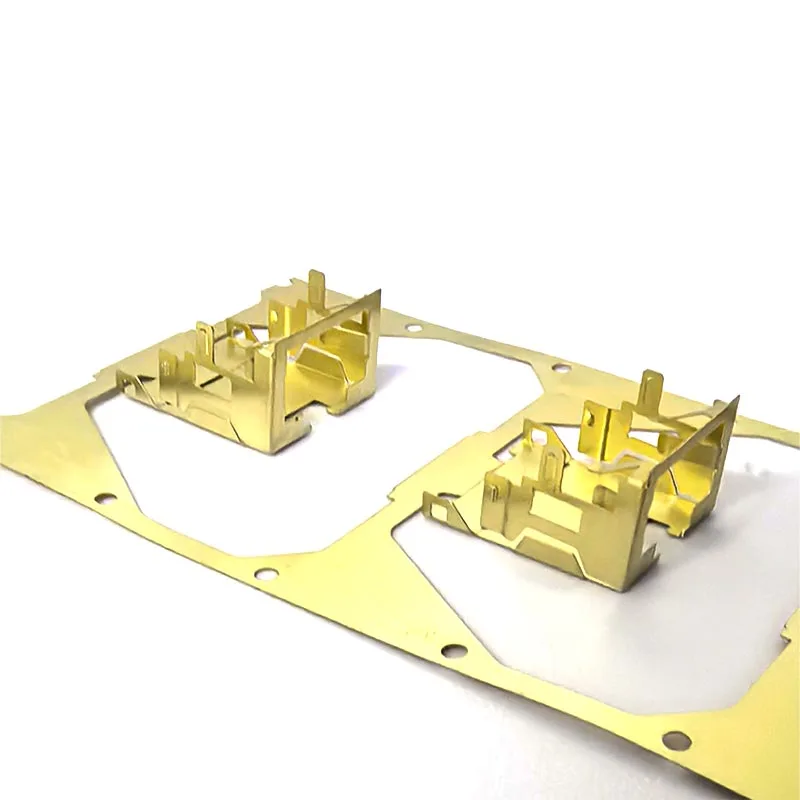

The production of micro-parts in the electronics industry is inseparable from precision hardware molds. The precision of mobile phone SIM card slot dies reaches 0.005mm, completing cutting, bending, and forming processes through continuous stamping, with a single production capacity of 1,000 pieces per hour; the pin dies for computer connectors adopt high-speed stamping technology, with a punch life exceeding 1 million times, ensuring that the pin spacing error does not exceed 0.01mm and guaranteeing stable signal transmission.

In home appliance manufacturing, hardware molds improve product cost-performance. The fin dies for refrigerator evaporators realize automated stamping; after processing a 0.3mm-thick aluminum foil through the mold, the heat dissipation area is expanded by 3 times; the punching dies for washing machine inner drums punch 3,000 water-permeable holes with a diameter of 2mm on the stainless steel drum wall, with hole position deviation less than 0.1mm, balancing dehydration efficiency and structural strength.

In the medical device field, hardware molds ensure the safety of parts. The jaw dies of surgical forceps undergo mirror polishing treatment, resulting in a stainless steel surface roughness of Ra ≤ 0.8μm after stamping to avoid bacterial residue; the push rod dies for insulin pens use food-grade steel to ensure no impurity precipitation from parts in contact with drugs, meeting medical-grade standards.

From large industrial components to micro precision parts, hardware molds, with their customized design and efficient production capacity, have become the core support for various industries to reduce costs, increase efficiency, and improve quality, driving the manufacturing industry towards precision and scale.